CVA and the Hollingbury Industrial Estate

An account of the development of the factories of CVA (later Kearney & Trecker) on the Hollingbury Industrial Estate, Brighton

The Hove based Machine Tool Company, known for much of the 20th Century as CVA, was founded at the end of World War I. Its headquarters for over 50 years was in Portland Road, Hove, near the bottom of what is now Olive Road.

Wide range of products

The Company produced a wide range of engineered products, and experienced steady growth and expansion during the 1920’s and 1930’s. In 1926, the Company first became involved in the manufacture of metal cutting machine tools. During World War II its manufacturing expertise was used extensively towards the war effort. Because of this the Company expanded to a number of other sites in the Brighton and Hove area. Following the war the Company was one of the largest manufacturing employers in the area, employing well over 1000 people.

Post war period

During the post-war period the size of machinery that the Company was producing increased in size. The CVA Dieing Press was one of these larger machines. Also for many years the Company had ties with the U.S. machine tool manufacturer Kearney & Trecker of Milwaukee, Wisconsin. Machine tools produced by Kearney & Trecker were also very large, some weighing many tons. A number of these U.S. machines were to be produced by CVA, for the U.K. and European markets.

Beginnings of Hollingbury Industrial Estate

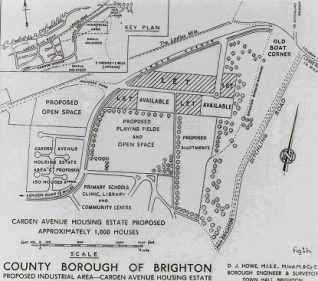

At this time Brighton Corporation had the forethought to consider the provision of employment. It proposed to build an Industrial Estate to ensure the prosperity and employment of local people. The proposed estate was to be built on the outskirts of the town, north of Patcham, below the junction of Carden Avenue and Ditchling Road.

Work started on access with the construction of Crowhurst Road in 1946. Figure 1 shows the proposed layout with some plots already let. The first of the new factories was completed in 1948 and from then on the new Hollingbury Industrial Estate really took off.

CVA’s first factory on the Hollingbury Industrial Estate

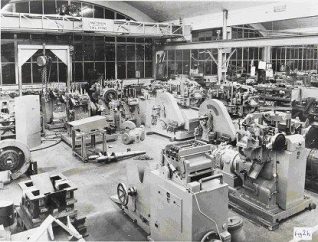

The CVA site in Portland Road, which was called No 1 Factory, was in the middle of a residential area. Because of the growth experienced by the Company during the war and post-war period, plus the increased size of the Company products, new facilities were required. The Hollingbury Industrial Estate had great potential and the Company decided on a purpose built factory with grand frontage onto Crowhurst Road. Wells Thorpe were the consultant architects and the building, now the headquarters of the Evening Argus, was completed in 1952. This was originally used for the assembly of Dieing Presses. Figure 2 shows the inside of the new CVA factory Die Shop. The unusual vaulted roof can be clearly seen. This was designated No 2 Factory.

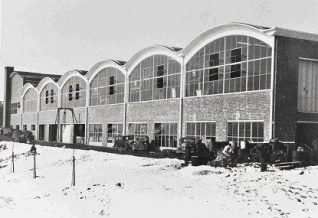

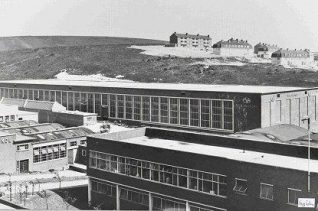

With environmental forethought, Brighton Corporation had the industrial estate built into a natural fold in the South Downs, barely visible from all but the southern approach. The hills on three sides and uneven ground were to cause problems with future CVA developments on the estate, as we shall see later. Figure 3 is a rare view of the rear of the new factory. In 1952 the rear of the factory faced open playing fields and a children’s playground, Carden Park, which sloped away to the south.

A second new factory for an expanding business

Although the new No 2 factory was over 50,000 square feet in area, this was still not enough to meet the needs of the expanding business. Also the new Portland Road development, completed in 1953, was mainly office space and not suitable for assembly of very large machines. This new type of machine, for the automotive industry, was called a Transfer Machine and could produce engine blocks, or like components, economically. However it was massive in size, some up to 200 feet long and hundreds of tons in weight.

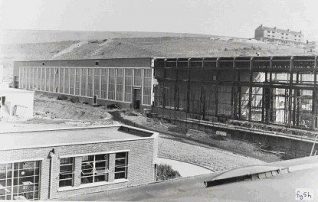

The Company decided on a further factory development on the Hollingbury Industrial Estate, 50 meters from the No 2 factory. London architects Townsend were used for this massive undertaking. Levels were set by the surveyors on the uneven ground and work was started in 1956. Figure 4 shows the steel skeleton viewed from the front of the No 2 factory in Crowhurst Road. In the background, on top of the hill, the footings for the flats at the end of Cuckmere Way can be seen. These flats were built at the same time. No sooner had the steelwork been erected, than the Company realised that the massive new building would not be big enough! The architects were quickly consulted and it was decide to increase the size of the building by extending in front. However the uneven ground was to cause a major problem, as the land in front was 3 meters lower. There were 2 alternatives; either build the level of the ground up, or have a 3 meter level difference inside the new factory. The latter was decided and construction of the new section was started, making the total area 85,000 square feet.

Figure 5 shows the steelwork of the new second section, with the rear part of the factory almost complete. The photograph has been taken from the roof of the No 2 factory, which is now the Evening Argus building. On top of the hill, work on the first of the new flats is also almost complete. Figure 6 shows the newly completed factory. This photograph seems to have been taken from high up on the opposite side of Crowhurst Road, currently the filling station end of the Asda car park. Figure 7 shows a view of the inside of the new No 6 Factory. Note the 30-ton overhead crane with the operator sitting up in the control cabinet. This was required to lift the very large components and machines.

Prosperous times: the 1950’s and 1960’s

The late 1950’s and 1960’s were to be the Company’s most prosperous times. In 1957 Kearney & Trecker Corporation invested 1.5 million dollars in the Company. A new manufacturing plant was built at Littlehampton in that year, and six of the most sophisticated computer controlled metal cutting machines (N.C.) were installed there. This was the second largest N.C. installation in the world, the largest being in the U.S. factory. Transfer machine sales to the automotive industry were doing very well. An example of this was an order from diesel engine manufactures, Perkins of Peterborough for a £900,000 transfer machine, to be built at the new Hollingbury factory. In today’s terms an equivalent order would be worth over £40 million. The manufacture of Kearney & Trecker N.C. machines in Brighton was planned. Record sales for 1965 were nearly £6 million. It was not unusual to have government ministers or executives from Fords or the like visit and the Company was involved in many major projects like the Anglo-French Concord. Prospects for the future looked bright! The area prospered as well, it was estimated that the Company put over £1 million into the local economy. Again, a huge amount of money by today’s terms.

Kearney & Trecker take over the company

1966 was to be a year of change for CVA. In June of that year, Eric Aron, who had been managing Director since 1934, sold the remaining family shares, amounting to 308,606 ordinary shares, to Kearney & Trecker Corporation. This brought the total number of ordinary shares held by Kearney & Trecker to 966,284 out of the 1,000,000 one pound shares issued. Mr Aron resigned as managing director and the company name was changed from CVA to Kearney & Trecker. A new managing director, Bill Neill (fig 8) was appointed by the parent company. Scottish born Mr Neill had been awarded the M.B.E. in 1946 for his services to the aircraft industry during the war. Following the war he had been Production Manager at de Havilland Propellers Ltd.

Building over Carden Park

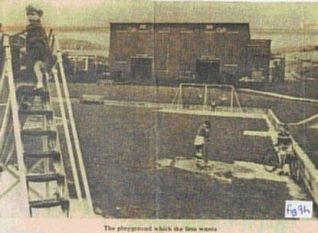

It was perhaps with insight into the future that the Company decided to build a new factory and consolidate the numerous factories in the area onto one site, Hollingbury. The No 2 and No 6 factories were 50 meters apart, the Company’s plans were to build a massive new factory, linking the 2 existing buildings. This would house production and in particular assembly and a centralised stores, from the other factories in the Brighton area. However Carden Park occupied the site between the 2 existing factories! Figure 9 shows a view of Carden Park, taken from the area where the MFI building now stands, looking towards the massive end of No 6 Factory. The vaulted roof of the No 2 factory can just be seen in the top left hand corner.

Discussions were held with Brighton Council in the summer of 1966. Although the proposal was supported by many of the Planning Committee, the Parks Committee were strongly opposed to the release of the 5 acre park. This was widely reported by the Evening Argus at the time. Concerns were also raised in Littlehampton, if the proposal was approved there would be job losses at the Fort Road, Lineside factory. Kearney & Trecker were also one of the largest employers there! Brighton Council asked the government to intervene. The departments concerned, Ministry of Housing and Local Government, although wishing to help, were not able to as the procedures had to follow certain law. In the mean time Littlehampton Council were hopeful that the Hollingbury proposals would be refused and perhaps a move to centralise operations in Littlehampton would be possible. The Company played its trump card by producing a letter from East Kilbride Development Corporation. The letter was offering the Sussex company industrial development and housing land in Scotland. Brighton Council had many reasons for concern, apart from the £1 million the company put into the local economy and 1700 jobs. Also the factory buildings were leased from Brighton Council at a rent of £42,000 per year, plus £24,000 per year rates. The Council had borrowed the money to build the factories and the Company was repaying this at 2.5% above the borrowed rate. If the Company moved to East Kilbride would anyone else want the huge factories? This was the persuading factor, the Parks Committee relented and the proposal was approved. The building of No 8 assembly and stores factory was underway.

A technical challenge for a young engineer

The uneven ground, which sloped away lower than the No 6 factory, again caused the surveyors problems. This time they decided to build up the level to the same height as the lower floor of the No 6 factory. This was done using ashes from the Southwick Power Station, which were transported to the site by lorry. Many thousands of tons were deposited, and by damping down the ash as it was laid, it made a very suitable foundation for the heavy machinery. The new building was to be 70,000 square feet and connected to the 2 existing factories would make a total of over 200,000 square feet! The next decision was how to connect it to the No 6 factory. There were a number of alternatives, but by far the most technically complex was to demolish the massive end wall of No 6 factory seen in figure 9. Dave Gunn was the young Kearney & Trecker Project Engineer and the architects wanted to know which method the Company had decided on. It was a massive decision for the young engineer but he chose the most complex and expensive method, to demolish the massive end wall. This was to prove to be a sound decision, as it provided a good link between the existing and new buildings, where massive 20 and 30 ton cranes overlapped, enabling heavy machinery to be easily moved between the two. This was named the “Link Bay” and lorries could also drive right inside to be loaded within the bay. Also it made the two factories as one, running parallel the full length of Crowhurst Road. One could barely see from one end to the other, as it was over 800 feet long.

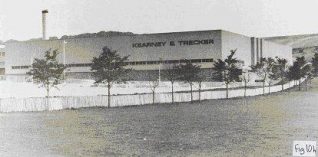

The new factory was completed in 1968 and is seen in figure 10. Land in front was used as a car park and the Company had options for further extensions out to the road. Gradually the other factories in the area were closed and production was moved into the new building. This started with the closure of the heavy machine shop, Lineside, at Littlehampton and the Cricket Ground assembly plant in Eaton Road, in 1969. Production at Portland Road and Coombe Road was gradually transferred to Hollingbury and they both closed in 1973.

Financial difficulties ending in receivership: the late 1970’s to 1994

The Company was never again as profitably as it had been in the 1950’s and 1960’s, and by the late 1970’s got into financial difficulties. The government intervened and the business amalgamated with Marwin Machine Tools of Leicester who were also in difficulty. The name was changed to Kearney & Trecker Marwin (KTM). By the early 1980’s, with the Company still rarely very profitable, control was transferred come under the guidance of Vickers, who put Michael Bright in charge as Managing Director. In the early 1990’s Mr Bright headed a management buyout, and the Company name changed yet again to Flexible Manufacturing Technology (FMT). However the land perhaps seemed more important than manufacturing. First the lease on the car park was sold and the MFI store was built on the land. Next the 1948 No 2 and 1968 No 8 factories were sold to the Evening Argus, who built the massive Print Room in the assembly factory. A new dividing wall was built and the Company consolidated into the No 6 factory.

For a short spell things looked promising, new products were developed and the Company was involved in many high tech projects for the likes of Jaguar, Rover, JCB and Shorts of Belfast. Additionally exports were doing well, with the Company working on projects in Belgium, China, the U.S.A, and with government approval, Iraq. However the management decided to increase the product range by acquisition and purchased 2 failing machine tool companies. Both Nobel & Lund of Newcastle, and Kearns Richards from Manchester were in receivership. The Company also purchased the derelict Jotun-Henry Clark building on Crowhurst Road, which had been empty for some years. It was perhaps these investments, along with a decline in sales, which was to be the downfall of the Company. In February 1994 FMT went into receivership. The employees were made redundant, with a few kept on to complete existing contracts and help clear the factory. All the plant was sold off by the receiver and shipped out to the Far East. Eventually the building was sold to Sussex Stationers, British Bookshops and is now, following a complete refurbishment, their headquarters.

Comments about this page

CVA was not, as stated in the article, ‘near the bottom of what is now Olive Road’. It was actually further west along Portland Road on the site purpose-built as the Seeboard HQ building when Seeboard relocated its HQ building from the building at the bottom of Grand Parade, Hove now occupied by the City Council. I am not criticising but it would have been nice to see some mention in the article of the work of the Council’s Estates Department (later to become the Borough Valuers Department) led inspirationally by the Late Cyril Dutton. The Department was responsible for the development of that and other industrial estates in the town, and the management of the huge portfolio of land and buildings owned by the Council.

Reply to David Hibbard: It depends on how you define ‘near’ – two to three hundred meters along from the bottom of Olive Road, many would consider as near. Incidently the track that was to become Olive Road was originally dog-legged and in fact ran diagonally from the railway bridge south-westwards through the industrial estate, joining Portland Road at the enterance to CVA. I believe that Olive Road was straightened in the mid 1930s to join Portland Road at the present junction. As mentioned twice in my article, Brighton Corporation did an excellant job in anticipating the need for the estate and their environmental consideration.

Thank you Peter for a well crafted and informative addition to this excellent website. I worked for Kearney & Trecker and its name changes at various times (left twice, redundant twice) between 1971-1992. I do remember Peter (Inspection Dept) as far back as my apprenticeship when I was in the training school under the supervision of Gil Percy and Tom Muggeridge. Peter was an apprentice, one year in front of me. Post apprenticeship, I worked firstly in the Special Purpose Machine Division. Some of the people I worked with were Mo Porter (foreman), Frank Palmer, Wally Price, Colin Packham, Marvin Bronson and Roy Smith. I moved on to the Toolroom Section with Chris Symonds, Roy Cain, and Colin Murdoch, all under the expert guidance of Bill Sadler. Finally I worked in the Unit Build Section with Don Timms (foreman), Barry Muir, Douggie Brown, Charlie Benford, Mike Dixon, Eddie Osbourne, Rex Lowe, Les Lucas, Roy Crowe and Dennis Bailey. I’m sure Peter’s excellent contribution(s) will stir the memories for some of the thousands of ex-employees who passed through this once well-respected engineering company.

On the 28th April 2006 I received an emMail from Doug Valeriani who now lives in Australia. It seems that many of the old FMT CVA employees now reside in various parts of the world. I worked on the Automatics Division on their range of CVA Autos. Many employees of this firm still meet annually at the FMT Club in Franklyn Road, Portslade in the evening of the first Wednesday in December. All old employees are welcome. I would love to hear from any former employees that remember me.

I only looked up the name of Kearney & Trecker out of curiosity as the company I work for still uses their machinery. I found the article very interesting and I will let my work mates know about it.

Wow there are a whole load of names in the comments here that I remember as an apprentice. Tom Muggeridge and Gill Percy definitely shaped my future. A good friend of my sister married Les Lucas’ son – I still work closely with engineers in many industries training them to use CAD system Catia. There is still a KTM reunion at the KTM club near Christmas

Can anyone give me any information about the factory on the Hollingbury industrial estate that manufactured adding machines and sunstrand machines under the name of Underwood in the 50s

I worked for the company under its differant names from 1959 to 1987. The comments made and the names metioned brought back many happy memories. I now live in Lincolnshire and still work in machine tools for Newalls, part of the Danobat group.

Hi Connie! I believe that the Underwood Business Machines factory was one of the first factories completed on the new Hollingbury Industrial Estate in 1948. It stood directly adjcent to the north “cliff face” which now forms part of the Asda car park. Just in front of the Underwood building was a factory occupied by Elliot & Fisher adjcent to Crowhurst Road. I believe that these 2 became ITT Creed in the early 1960’s. Photographs and maps of the original factories can be found in Issue 21 of Sussex Industrial History ISSN 0263 5151.

What a great article. I worked in the firm continuously from 1970 to about 1993 and reading this article has triggered many memories of people and events back then. I have long been interested in the Kearney & Trecker and CVA days of the late 1950s and 1960s and this has filled some gaps. I still remember the impact I felt about the size of the place the first time I walked into the No 8 shop in 1971, even after the time I had spent in Portland Road . It’s also interesting to realise what was happening on the American side in the 1950s and 1960s. We were placed right in the forefront of engineering technology through our partnership with K&T. When we became KTM in about 1973, we began to row our own boat and K&T became our competitors. Lively times!

Found your article about CVA. very interesting. I worked for

the company at the Upper St. James Street location which

I believe was the old Kemp Town Brewery building, and the

No.2 factory in Hollingbury from 1949 to 1962. I have photos,

of myself and the lad,s outside No.2 on my last day before

leaving for the U.S.A.(California) where I have lived for 46 years.

I would like to update my last comment with a little more

information on my time at CVA. While at the Kemp Town

factory I worked in the planning office headed by George

Francis. It was during this time that the smallpox scare

happened and we were quarantined in the office until the health department sent out people to vaccinate us. I think

the whole factory and town was done, even the whole country. Not sure of the date, must have been about 1950. Some of the names at this time were, Percy Steer, Bill Smith, Cyril Moss, Fred Thomason, Ernie Vinal, Jack Rice, George & Derek Smith, Geoff Berry, Don Timms, Brian Staveley just to name a few that I can bring to mind.

We all went to the No 2 factory in Hollingbury. When I came back to Brighton on my many visits, I always dropped by to see the lads at No 2. Even went up to the County Oak Pub for lunch one time.

Message for John Stenhouse: Hi John, I’m pleased you found my article on CVA interesting, there are more on this website that may be of interest if you look at Eaton Road and Lewes Road. Very few people seem to know much of the Kemp Town factory, I would be very interested to hear about it if you wish to email me at: pedrogroves@googlemail.com. Very best regards!

I remember Bob Carden (although he may not remember me) when he was at Eaton Road. I was there for about 9 months during 1959 as part of my apprenticeship. I was assembling No. 8 autos. and I remember Bob being up the end near the canteen working on tooling for the No. 8 auto’s. I was at Crowhurst Road from 1959-60 working on the 10 ton presses. Good memories!

In the early 70’s I was hired as an NC applications engineer by Stan Renew. I still remember Stan’s horror in hearing that I had no expereince in machining cast iron. I tried to explain that coming from the aerospace industry where I had been programming K & T Milwaukee Matic Eb NC machines, all the materials we machined were high strength steel and aluminium alloys, and that I did not see a problem learning cast iron. He looked at me for a while and finally said we’ll take a chance with you even though you lack experience. Shortly after the Marwin Mafia came on the scene I left and worked for K & T Coporation in Milwaukee Wisconsin until 1991 when it too closed.

Hello John. it’s been a number of years since we last met back in Milwaukee, Wisconson at the old Kearney & Trecker facility. I was visiting the facility with the Canadian distributor, Williams & Wilson Ltd, from Toronto, Ontario with Dave Kreissel. You may recall working together in the NC Application Engineering Department under the supervision of John Kidd. I initially joined K&T-CVA in 1965 as an apprentice attending the College of Technology studying for the City & Guilds exam, on what they called a “block release program”, three months at class followed by three months working within various departments around the company. I recall working in the assembly section of the EA NC machines at the Portland Road facility; in the Special Machines (Transfer Lines) assembly section at the #6 factory, and then at the conclusion of my apprenticeship travelling to the Littlehampton facility working in the NC programming department until the facility closed and was transfered to the #6 factory. From there I was transfered to the NC Application Engineering Department back on Portland Road where you and I initially met. Today, I’m still involved with capital machinery and industrial equipment, living here in Charlotte, NC.

The above contribution should have been signed off as …. John Horn. I left Kearney & Trecker in December 1992 at which time I emigrated to Canada.

As far as I am aware, the only product manufactured in Brighton were manual typewriters. All adding and accounting machines and electric typewriters were imported from the United States.

That’s not a very nice remark to make about Brighton, especially on Christmas day, J. A. Dalby!!! Although Brighton is best known for its tourist industry, there was actually a strong (for the size of the town) manufacturing industry in Brighton. The “typewriters” manufactured in Brighton were actually “electronic teleprinters” made by ITT Creed and exported all around the world, probably to the states as well. I will be doing an article about Brighton and Teleprinters later, and will give you all the facts. Additionally of course, and not many know this, is that Brighton was known as “Coventry of the South” because of its toolmaking skills, normally associated with the city of Coventry. This was mainly because CVA had 1st class toolmaking facilities. The story that CVA stood for “Copy Very Accurately” is funny but not true, as apart from being good at manufacturing, design at CVA/K&T was also excellent. To say that Brighton only manufactured typewriters is a disgrace, I’ll also be doing an article about the Airbus and the connection with manufacturing in Brighton to set the record straight.

Peter, I hope the article you are writing will be a bit more accurate than your letter on this page! Manual typewriters were manufactured in Brighton by Underwood Business Machines Ltd.; electric typewriters, adding machines and accounting machines were imported from the States for sale in the UK. I should know as I was employed by them and visited the factory a number times. Get your facts straight!!

Peter, Reading your comments again I did not suggest that Brighton manufactured only one product, the Underwood factory only manufactured one product i.e a manual typewriter, the rest is as my statement above. One product in a place the size of Brighton I don’t think so there is always Brighton Rock as a second!

Hi John, lets try not to fall out over this, however your comment did suggest that Brighton only manufactured one product. Considering your comment was left on the K&T page, how on earth was anyone to know you meant, “only one product was manufactured at Underwood”? You do seem to think that Underwood was the only manufacturer in Brighton and that, without stating their name everyone would know who you meant. With respect, without knowing that you meant Underwood, and when stating “only one product was manufactured in Brighton” far more important Brighton manufacturers spring to mind, like ITT Creed, Gross Cash Registers, K&T, Pullars, Leytool. I now fully understand that you meant “only one product was manufactured at Underwood” but stand by my statement “to say only one product was manufactured in Brighton would be a disgrace”!

John, reading your comment of 25/12/09, and reading it again now, you do STATE that only one product was manufactured in Brighton, which is not true! By-the-way, I couldn’t say if Brighton Rock was manufactured in Brighton, it sounds like you might know differently? My facts are straight, exactly straight!

To Mr.P.Groves: Re your reply to J.D and his comment on only one product manufactured in Brighton. Where is all this industry now? Moved to China! D.U.Rex

Hi David, yes more recently some industry has moved to China, however Hollingbury Ind Estate, without being rude to the small manufacturers that are still there, went into decline many years ago, while China was still a “closed country.” If my memory is correct, decline started in the Thatcher years of 1979 onwards. Like the rest of the country, Hollingbury suffered with job losses, or redundancies as we called em! It was at this time that unemployment went from 1 million to 3 million, it was in the news every day. I remember the ritual of the Friday night news, when they had the “swing-o-meter” of job losses, it seemed to me as the biggest disaster since Dunkerque! Industry was not supported by the Thatcher government, in fact it got the opposite, a good bashing, and she then left her city slicker mates to make a good profit from the land. A good example of this is the KTM car park, sold off to MFI (where are they now?) which was the beginning of the Hollingbury decline. It was a dismal time for manufacturing, and in the 80s if you asked “who voted her in?” no one would own up to it! Recently more manufacturing has shifted out to Eastern Europe and China but the rot started ages ago.

John Nurse employed me as a sales engineer in the late 1960s for Kearney & Trecker (Milwaukee)Ltd. I continued with the company in a direct sales capacity until 1985 with the latter position as UK Sales Manager. We had a wonderful team of n.c. application engineers to support the UK & Export Sales Engineers. I would like to send my regards to all the KTM colleagues that I worked with during that time.

I remember Tommy Grieve well on CNC Sales!

Couple of updates: John Horn: Dave and Elaine Kriesel were at the K & T 2009 ‘Old Timer’s’ Xmas lunch. He’s still knocking down the “Silver Bullets” (vodka martinis). Tommy Grieve: So nice to hear from you. Remember when we were housed in those three mobile buildings at Hollingbury? It was wise to put the AEs in a building by themselves as the ribald comments would have not have sat well elsewhere. BTW The AEs in Milwaukee were no different, if anything they were worse!

Hi John Nurse. I was contacted by one of the USA Service Engineers Ron Cook to see if I could help him with some USA K&T history. Anyway I sent him a copy of a DVD I have with K&TUSA NC promotional films from the 1960s. If you are interested I could do you a copy, fascinating stuff!

Hi Peter, I would be delighted to have a copy of the DVD. FYI: When Giddings & Lewis acquired K & T in early 1990, the place was stripped of most historic information by employees who did want to see it thrown in a dumpster as the factory was being emptied out ready for the new owner, Quad Graphics Inc. Much of it is now at the West Allis Historical Society, to whom I would donate the DVD.

An interesting read but my reason for writing is because I have a question. I own a worn but still usable CVA model 1A series 3 lathe, built in 1957. I know of a series 1 machine (with the rounded styling) but don’t know where the series 2 fitted in. Has anyone any recollection of when the series 2 was in production, and what made them different from the series 3?

Hi John, email me your postal address, on pedrogroves@googlemail.com

Hello Peter Groves. I’ve just been put in touch with this page by Micky brittain. I joined ktm in 1974 after 15 years in the RAF. I started on the big beam aerospace machines at the south end for four years as an electrician learning the trade. What a good apprenticeship, even for a 30 year old new boy. I then moved upstairs to the drawing and design office where I remained until the company was shut down by the wonderful MD. He would have made a good MP. I hope to get a reply from you. We talked enough on the shop floor. Best regards.

Hello Paul, really nice to hear from you after all these years. Of course I remember you well. I started in 1970, but did not move to the assembly floor till about 1975, on the Modula line with Joe Ryder and Fred Dyson, this was just shortly after the merger with Marwin Machine Tools. Soon after this I did spend some time on the big aerospace machines, it was probably then that I met you, Les Freeman and Eric Lowen? I would love to hear from you as I am just writing a story about the “Biggest Machine Tool in Europe” the 200 Series Trace, built at Brighton. I’m pretty sure you were involved? All the very best,

I worked at KTM for two and a half years when I left school in 1980. The first year was spent at School Road, Hove and then 18 months in the training school under Gil Percy. I left to finish my ‘time’ elsewhere. Looking back it was a good apprenticeship. I was and still am friends with Carl Vine, who ended up working in inspection until the factory closed. I enjoyed your article very much and you were absolutely spot on about Thatcher Mr. Groves.

Hi Barry, I too did my apprenticeship at School Road and then with Gil Percy at Coombe Road, before moving to Hollingbury about 1972/3. I worked with Carl on inspection for many years, and have been going swimming/golf with him every Thursday since about 1990, and still go now!

Hello Peter Groves . I am an Indian from Mumbai and I am having goose bumps as I write this. After purchasing two CVA dieing presses from a recently closed company called GKW which was established by the British GKN in the 1940s. I googled CVA, then Kearney & Trecker and landed at your website. I loved reading your article and others’; the photos took me to another era. The whole site is well maintained. In fact, I forgot why I visited the site in the first place. Can you help me obtain a maintenance manual of 50 ton CVA Dieing Press? The undercrank design is unique and sturdy. If there is anyone who can help, please let me know. my email address is welknowntools@rediffmail.com.

Hi Vidyadharan (sorry but what is your first name?) Firstly I was so pleased to hear from you all the way from India, and secondly that the old CVA Dieing Press was in use still after all these years in India. Machines were really “designed to last” way back then and have probably out-lived those that designed and built them. I’m really sorry but I don’t have a manual for any of the Dieing Presses, I think they were phased out around 1968 when CVA started to build K&T NC machines. I hope you are lucky and hear from someone else via the web-site, who can help you. Your message “with goose bumps” was really nice to hear, I feel exactly like that when I read an interesting old history story, particularly one that I can relate to, like CVA. More to come on the web-site later, about KTM and the biggest CNC Machine Tool in the world, look out for it. Finally, on a more personal note, I really want to visit India. I think it has so much of interest and culture that one day I hope to visit. Good luck with finding the manual, and all the very best.

Hello Peter. I am a residant in Hollingbury and have just wrote an article on the history of Hollingbury Industrial estate and surrounding area using some of your information and three pictures. I would like to add my article to Hollingbury Hello Newsletter and on the website (www.hollingbury.info) but first I wanted to ask your permission. I will add a link to your page if you would like. Thanks.

Hi Jo, no problem at all, go ahead as you wish! Two or three stories and lots of photos to come about the industrial estate later on. I’ll look out for your article, when will it be published? pedrogroves@googlemail.com

If only every factory estate had so enthusiastic a chronicler as Peter! Does anyone know the origins of the C.V.A Dieing Press? Perhaps it was made under patents of William Frank Golding of Bristol who designed printing and metal working presses? (Perhaps he had connections to Strachan & Henshaw?) Kearney & Trecker Ltd do not seem to have had patents in this area. Also, was the term “dieing” for a high-speed metal blanking press first used by C.V.A, as previously it was used for “clicking” presses in the leather etc trades?

Hi Martin, I don’t know the origin of the CVA dieing press, assumed it was their design, but I don’t know. Others, who visit this page, might be able to help, one is Henry (John) Stenhouse who was a toolmaker on the dieing presses, let’s hope someone can shed some light? I think you are correct that K&T did not have any patents on them, plenty on NC technology. Also I believe that CVA were well into the dieing press before K&T owned CVA. I think I might have an article in my loft about the dieing press, perhaps I’ll dig it out.

I have always wondered what happened to KTM. Spent many a happy hour keeping the 400 and 1500 machine tools in production at our factory in Chippenham. Either replacing proximity switches or reloading the systems tape into the Kongsberg CNC2000 control. The DC Gettys motors always seemed to end up full of coolant. Visited the factory in 1978 for a training course but can’t remember much else about it. Would be nice to know where the cnc’s ended up - I think they went to India. Please put some info and pictures on the site.

Hello Peter Groves I’m an ex service engineer on the old machine systems, mostly electronics. Model 3-5 axis was my speciality - ended up in Norway for good after installing 8 machines here. Any chance of a copy of the old DVD. Contact me on my e-mail address.

[comments editor – Hello Alan, we are unable to publish email addresses without permission. If you would like your email address made available for Peter to contact you, then you can add it to a new posting. Best wishes]

Hi Alan, I got your email from some days ago, and the DVD was sent last week, enjoy. I did reply to the email you sent me, strange you have not seen it.

Love Peter Groves map. Looks as though the initial plan was to also extend the Ladies Mile Road to provide an additional link to”The Factories” as we called them. Actually I remember in 1947 when there was nothing there at all. This was the site where kids from the Patcham side of Carden Avenue had mock cowboy and indian battles with those from the Hollingbury side.

I just received a short email stating that Alan Pierce had passed away. Could someone confirm if this is correct? I remember hiring Alan as an Applications Engineer.

Message for Martin Cummins; re your question about the origins of the CVA Dieing Press. I just found a CVA catalogue in my loft and it states that the CVA Dieing Press was a Rockwell product. It also turns out that the Rockwell company have their origins in Milwaukee as do K&T. Will try and find out more, best regards.

Hi Peter, and to all old work colleagues who started in 1962. I have very fond memories off all the people I met and worked with. Pity what’s left of us can’t have a meeting. Regards

Hi Brian, what’s stopping us having a get-together? Just contact me pedrogroves@googlemail.com

You may or may not remember me John but I was a young apprentice with you in the AE Dept. and went on to stay there until the plant closed. Alan Pierce did pass away recently, I went to his funeral, as did Tommy Grieve only just before Christmas. They were both fine men and engineers. I am still in touch with Keith Gore, Barry Ford and Geoff Smith who I know you will know.

I worked for Kearney & Trecker from 1964 till 1969 as an apprentice electrician on the maintenance dept starting at Portland Rd and moving to all the other factories. I can remember the huge blast furnace in the foundry shop and watching the sparks flying at the 3pm pouring. I was always repairing the magnetic crane that picked up the scrap metal from the train sidings that fed the furnace. I can remember working with two other guys, Arthur Plum and John ? and we had to locate an underground high voltage cable so we could connect it to new machine in the heat treatment shop. The only way to find it was to divine for it. We found it. And I can still do it.

Hi Richard, I’ve got a great photo of the newer big foundry in Portland Road, I believe it opened in 1930. It may have replaced the small one which opened about 1926/7, or they may have run in tandem? It would be good to put the photo and a write up by you about it, if you are up for it? I was told about the fact that there was a train siding for the unloading of coal and steel, it would be good to hear more about it. Have a look at the Portland Road page, perhaps you could point out the foundry from the aerial shot? Let me know if you are interested in doing something about the foundry?

Hello Peter, I have just had a rather belated look at your site, and espied the inormation that you have dug out concerning the C.V.A. Dieing Press. Now that I know that it was a Rockwell design, this has put me on entirely different tracks! I am now wondering if, when the K & T range of tools displaced the Dieing Presses, the design was adopted by the Coventry firm of Matrix, to become the Rockwell-Matrix? I appreciate you looking in the attic – I am steeling myself to do the self-same task! Anything further, such as possible patent list on literature, or early history, would, as always, be appreciated. I do hope Brighton Corporation is helping to fund your service, as it is now a part of the Social Fabric of the area! P.S. I have now located a manual for Mr.A. Vidyadharan’s C.V.A 50 ton Dieing Press, and passed info on to him. My e-mail is “martin_cummins@magnetuk.com” should anyone want to contact me regarding C.V.A Press history. Regards, Martin.

Hi Martin, I’ve sent you a separate email, however also for those out there who know more about the CVA Dieing Press, I would like to know more. How did it come-about, that CVA were manufacturing the Dieing Press, and was it just a Rockwell design, built under license by CVA, or was it a joint venture? Strange but Rockwell Machine Tool Co Ltd, of Edgeware Road London, surely were in competition with CVA? And what, if any is the connection with Rockwell Automation of Milwaukee who manufactured the Allen Bradley NC and CNC Controls, which powered machines built on both side of the Atlantic by K&T? It looks like the Rockwell CVA Dieing Press did not go to Matrix of Coventry (who later became Matrix Churchill), it appears that CVA/K&T stopped building the Dieing Press around 1970, and it seems that since 1973 the product and intellectual property rights have belonged to TMA Engineering of Birmingham, I will contact them and see what they know! They can be found here: http://www.tmaeng.co.uk/powerpress/

I was very interested in the comments about the CVA. I worked there from 1952 until about 1982 and ended up in charge of the welding shop and have many happy memories. I used to hear from Jimmy Smith who ended up in the buying office but I have lost touch with him now; has anyone any news about him?

Hi Malcolm, I remember you but not Jimmy Smith? Wow, that was some welding shop, talk about heavy duty! Many of the major components welded together were huge, inch plate welded together was not uncommon. I doubt there is anywhere in Brighton where that type of heavy welding could be done now!

I started my apprenticeship as a Toolmaker in the factory in Upper St.James St. before moving to No.2 in Hollingbury. After progressing through the m/c shop and D.O. I ended up on the bench next to Jack Cook, my mentor in the Press Tool Dept. A great craftsman, and a gentle giant. I can relate to most of the names in the comment by Henry Stenhouse (4/01/09). Soon after completing my “time” I emigrated to South Africa and in 1963 I moved to California and ended my working days designing and building precision tooling for the semiconductor industry in Silicon Valley. My CVA apprenticeship served me well. My father George Solly started work in Portland Rd. in 1922 and ended up in No.6 as a senior manager when he retired.He was awarded a M.B.E for his “Contribution to Industry”. Sadly we Brits don’t seem to make much anymore, I think all the best Toolmakers must be in China.

Peter, well done for putting this history together for us all to reminise over. I started my apprenticeship at School Road for KTM in 76, one of about 40 others. Then I was taken under the wing of Gill Percy and his assistants to try to make somthing usefull out of us. I still treasure the great experiences we had there as young engineers and how that shaped my future in the industry. The sense of family was very strong and I made some life long friends during my time there. I moved on in 88 and was very saddend to watch its demise. I remember a figure of over 2000 people when I started. A few years back I was pleased to see that Hugh Fermer had put a few KTM memories together at the Amberley chalk pits museum. I’m not certain if they still exist today.

It was good to hear all these comments from ex members of K&T CVA. It was a good firm at the time of investment by K&T in the States, it was a great pity that the quality fell off at the time of the H60 saga. I was a young chap just finishing my apprenticeship. I was thrown in as a service man working everywhere trying to carry out control / mechanical mods. If only the UK could follow the quality standards of the Far East,

That’s a tad unfair Phil, it was a good firm even before investment by K&T, there are still many ex CVA workers who will vouch for that. Certainly it was not the quality of manufacture that fell-off at the time of the H-60. I know from other sources that the “technology transfer of the H-60” were difficult times. However the fact that many mods had to be implemented in the field, imply there was a design problem. More probably was that the exact design of the USA was not transferred, the Control System was different and perhaps the transfer not smooth. Another point was that the H-60 was new ground breaking technology, and bound to be frought with problems. Another point Phil, the H-60 was not a K&T product, it was owned by Gorton. Final point Phil, if by the Far East you mean Japan, yes quality from Japan is very high, however I deal with many Far East countries on a daily basis, and I don’t find their quality anywhere near to that in the UK, some are dreadful.

I’ve just been reading the desk diaries of my late grandfather Dermot London. He was a sales director at K&T/M for many years. The diaries, written by his PA Heather, reveal how he flew all around the world obtaining export orders. Poland in particular comes up again and again. Thank you so much for this article, it made the diaries come alive!

Steve, Derry was so important to K&T / KTM, so many huge orders which brought prosperity and work to the town. I’m going to try and get a story about the “Special’s Division” on the site some time in the future. There were some huge machines built by that division, for important companies all around the world, but Poland was prominent, at a time when it was far behind the Iron Curtain; Derry was involved in them all. Think I even have some photos of him at work in Hollingbury!

Thanks Pete.! My Nan says she has many newspaper clippings about K&T which I’m hoping to see sometime soon. If there’s anything you don’t already have I’ll copy them to you.

I am just writing up some memories of my Dad – Mike Greenfield who sadly passed away last week. Dad worked for KTM at the Hollingbury site as an engineer for many years. Reading your comments on Poland helped me remember that my Dad travelled to work in Poland for KTM several times. I remember that he used to tell us that the authorities took his passport until the next engineer turned up. We were always grateful that KTM sent the next engineer so we could get our Dad back! Thanks for a really informative website.

Peter! How right you are. I was the home trade and then export clerk for Creeds from 1965 – 1971. For many years I was working flat out all day arranging consignments for many foreign destinations, including the British Antarctic Survey. The home front also was very well served; a major recipient being the Post Office. Thousands of teleprinters ended up all over the world. In its time, Creed was anything but a minor production unit. Best wishes.

This is a message for Bob Carden. As one of the ex workers at Kearney and Trecker I have to tell you that the old fmt club has been sold to a developer. I know this as I was one of the life time members and got a share out for the sale. Also I worked at Portland Road stores on night shift in the late 60s until it closed and moved to Hollingbury where I was one of a hand-full of men that set the new stores up. I also remember the tea girl who used to come around with tea and food. Also I worked at it creed in the early 70s and I can tell you these were electric machines and they were made there.

Hi Peter, I’ve been sorting through my Grandfather, Derry London’s KTM cuttings, photos etc and knowing that you wish to do a story about the Specials Division would be happy to show them to you. If you could contact me at this address maybe we could arrange something. Steve Hussey.

I Steve, I don’t see your contact address anywhere, mine is pedrogroves@googlemail.com, I would love to see those photos!

I was an apprentice at School Road in 1968 doing pattern making, then working in a pattern shop in Portland Road until I was made redundant after I finished my apprenticeship. Are there any other people around who worked in the pattern shop ?

Hello to all! My name is John and I am from Greece and recently I bought a Kearney & Treker machine. The model is 307 s12 and up in the machine model decals Daewoo. Unfortunately some key components have lost . For example one such part is the gear for vertical head.

Please if you know where I can get parts for this machine?

Thanks!

You could be in luck Gianni, there is a K&T Christmas reunion every year, we will meet this year on 4th December, I will ask the guy who used to run the “Spares Department” if spares are still available for the S12 Milling Machine!

I now live Turkey but I worked at Coombe Road C.V.A in the 1960s. I was in the UK recently and met up with a friend who I worked with at C.V.A – haven’t seen her for about 50 years. We spoke about the time we worked there, also at Portland Road. My father and uncle at Portland Road and at Hollingbury for 25 years or more when we were kids C.VA. Always had a Xmas party for the works’ children – it was held at the Hollingbury factory and we all got a present – happy days.

Thank you Peter – I will wait for news!

Hi Gianni, I was told that the S12 spares are no longer available. Perhaps you can leave a message on some other social media site for someone who is scrapping an S12, and purchase some old parts? Sorry again!

What no one will remember is that CVA had a garage for the repair of vehicles in Chappel Mews off Waterloo Street Hove in the 1960s. I know this as not only did I work at various CVA factories as a machine tool fitter, but I also had a lockup garage opposite theirs in Chappel Mews.

Wow Dennis I didn’t know that! They also had a garage within the Hollingbury factory, it employed about 3 or 4 mechanics!

Peter a little further info – I think it was originally an EH Jones lock-up garage, then going over to CVA there were two mechanics employed there – one of them had a funny name so I remember it - may have been a nickname not sure, it was something like Zoonkie – he may have been foreign, he had a long beard. They were very friendly and would often lend me tools to fix my motorbike.

Thank you very much for your time, Peter!

To Peter Groves, many thanks for your effort on these pages, they made many memory’s from my time at KTM (1972-1977) come flooding back. Many of the names were part of my youth, Les Freeman, Mo Porter, helped me on my way in life and I’ve never forgotten them. Will there be a KTM social meeting again in December this year? Did you have a house called ‘Electra’ or something like that? Hope your doing well! Colin Lucas.

Hi Colin I’m glad you enjoyed these pages, I’ve been very busy for some months, but there is still a lot more to come on Hollingbury Ind Estate, watch this space! Don’t know anything about Electra, it must be someone else!

What a fantastic read, going back through and seeing all the names from way back. It certainly was one of the most enjoyable and rewarding times in my working life. Only two days ago I met up with Alan Still who I worked with on Special Purpose tools and we were saying “I wonder where they all are now”, so I put in the name of Marvin Bronson and up came this wonderful history. So many names that came back to me at a time when British Engineering was something to be proud of. I can remember the day I was told I had been given an apprenticeship at CVA/Kearney & Trecker at the age of 16 and I considered myself really lucky to get with such a company and enjoyed every minute of my time there right up to when engineering in this country started to “die”. I shall look through this again now, no doubt several times, and relay it to Alan. By the way, can anyone give me details of the December “get together” of the KTM Social?

The Christmas get-together is normally the first Wednesday of December in the Cricketers pub by the cricket ground. Probably watch this page and someone will post the date!

My dad worked for KTM in the late 70’s early 80’s. He also played for the KTM football team. He died very suddenly at the age of 34. I remember Des, Terry and think the managers name was Dave. Dave always wore a flat cap and drove a tiny white car!

Hi Dawn, I remember your dad very well, he was about the same age as me and a few others, who were all work mates together in the same area (NC Assembly). It was a massive shock to us all when he died at such a young age, because he was very well liked. Dave Hilton was the manager of the football team, and you are correct regarding the cap and white car. Kind regards!

I worked in the Hollingbury heavy machine shop on nights for two years from 1968 till 1970 on the Swift-Summerskill Plano mill and I have a photo taken of me by my Dad working this machine if you are interested. Regards

Hi Julian, I would like to see that photo, if you can scan and email me a copy: pedrogroves@googlemail.com

By accident I came across this interesting article and postings from past employees. My father, William Ronald McNuff, (‘Ron’ or ‘Mac’) 1902 – 1982, served his engineering apprenticeship in Glasgow and eventually joined CVA Lucas in Hove during the 1930s. I recall asking him why he left as he told many stories of his time there, and he left as he didn’t want to become a manager. This may have occurred at a time when there was a takeover of the old CVA factory. He continued happily at another firm in Hove until he retired aged 65 yrs. Dad was always fiddling in his shed, a whiz at repairing dynamos for the neighbourhood and also a gifted woodworker. A very kind ‘gentle’ man.

Hi Zena, originally (1917) CVA were CAV and connected to the company Lucas, probably you should look at the Portland Road pages, here: http://www.mybrightonandhove.org.uk/category_id__1787.aspx – this is where your dad would have worked.

Hello, I stumbled across this site talking about K&T this afternoon so thought I would google it as I worked in the cost office in Hollingbury during the summer of 1972, coming down from Manchester. A great company to work for, excellent facilities. I used to collect the clocking in/job cards on the shop floor and balance the hours. The lads on the floor would have me on. As I was collecting the cards from holders on the walls I would often feel something hit my foot and on looking down would see a washer besides my foot. I never saw who rolled them as on looking around for the culprit I would only see the engineers busy at work. It seemed so funny. Only name I remember was my boss Vic Shepcott, I think. A great three months there.

My Dad, George Pickett worked for CVA/K & T for most of his working life. He was the Import/Export Manager until he took early retirement. I believe he started out as a Clerk at Eaton Road or Portland Road. He used to work with Rod Summerscales and Greg Ash. I can remember when we lived in Woodingdean and it was snowing really heavy my Dad had to stay and sleep in Hove at a colleagues house as the buses had stopped running. My Dad used to speak several languages and so it was his job to translate for the foreign visitors to the factory. He used to have to entertain them in the evenings and would take them out to places like Eaton Gardens restaurant in Hove, Il Parmigianos off St James’s Street or the Black Lion at Patcham. My Nan was a cook at the Portland Road site in the 1950s and it was through her that my Dad met my Mum.

Does anyone remember my grandad, Bert Willis, who worked for CVT in the 1960s?

Does anyone remember which company supplied the pension scheme? I worked there for about 10 yrs from 1963/4.

I worked in the factory that produced parts for cookers do you have anyone who knows about it please?

I was also wondering about the pension scheme. I cannot remember how long I worked there but I finished my apprenticeship there after being made redundant from Beagle aircraft in 1969. I worked as a sheetmetal worker under Pat Collins (old cock) and Bert Tate at Coombe Road before moving to Hollingbury.

To all who are interested in the pension scheme, the info I have is as follows:

K&T/KTM traded as FMT in 1994 when they went into receivership. The administrators put the FMT Pension Fund in the hands of William M Mercer of Chichester, the full address is: William M Mercer Ltd, Westgate House, 52 Westgate, Chichester PO19 3HF.

However, around 2005 it was transferred to Legal & General, their full address is: Legal & General, Kingswood, Tadworth, Surrey KT20 6EU.

Probably L&G would be a good starting point!

On the desk beside me sits an agreement between our company (KDL Precision Engineers, which is still in existence as a subsidiary of Talbot Tool Co Ltd – the small factory fronting Crowhurst Road and shown in figs. 5 & 6) and CVA regarding the transfer of a strip of land to the south of our site which actually facilitated the building, presumably, of the extended, No.6 factory. The agreement is dated November 1958 and was drawn up at the behest of CVA, following a long running dispute between KDL and CVA over the encroachment of spoil from the building works.

This article, and the thread following it, is absolutely fascinating; history at its most local best!

As an aside, Gil Percy is well known to us, he was mates with a previous Works Director (Arthur Sullivan) and our current Toolroom Manager (Mike Dyer) served under him for some years.

The demise of KTM/FMT under Mike Bright was a tragedy, it was widely known on the estate that his prime interest was in the land, I even remember him approaching us at one stage – we were and remain one of the very few engineering companies left in Brighton. Indeed, I believe that KDL is now the ONLY original leaseholder on the Hollingbury Industrial Estate, which, year by year, moves ever further away from being “industrial”!

Hi Richard, thanks for your comment (and the photos you emailed me earlier today) I have lots more to come regarding the history of Hollingbury Industrial Estate, so watch this space. I still speak to Gil Percy, and I’m pretty sure I know Mike Dyer from way back!

I’m sure I know Mike Dyer, he was a tutor in the training school for a number of years with Gil Percy. When I worked in the KTM tool room I sometimes popped into Talbot Tool to purchase drill bushes over the sales counter for the fixtures I was making, so I am familiar with the company.

I have read some of the history of Talbot Tool as I’m interested in local industrial history and I have actually walked down Talbot Yard off Borough High Street in Southwark, London where the company’s roots lay before it moved to its first Brighton factory in Roedale Road during WWII. It’s such a shame the once busy Hollingbury indusrial estate has turned mostly into a retail park. I remember in the early 1970s when several thousand men and women used to be employed actually making things instead of a few hundred now just selling things. I’m glad to see Talbot Tool is still in business, and long may it continue.

Hi Peter: I guess that by now I am one of the oldest ex-employees of CVA/ CVA Kearney & Trecker/ KTM having had my 92nd last month.I can throw some light on the Dieing Press history. As I knew it the old No 2 Factory was originated by Eric Aaron at the start of the War in order to make war stuff. I never knew what exactly, but`bullet dies` were mentioned. As the War ended, so did the military contracts, which left Eric out on a limb. He thought of all the domestic products that had been shelved during the war and set about designing and producing things like vacuum cleaners, electric irons, chucks for DIY drills, to mention a few. He then bought an old 10, or was it 15, ton Henry and Wright Dieing Press which had found its way over here from the USA as part of their `Lease Lend`exercise. It was brought down to Kemp Town and stripped to its last nut, washer, and bolt, measured up and the drawings were made in the Machine Tool Office under Les Smith, who was Chief Draughtsman at that time. Shortly after that I joined the Tool Drawing Office on the other side of Charlotte Street. It was lucky timing for me as we were employed as the main designers and Manufacturers for NCR at Dundee, making Cash Machines. This gave me a good grounding in Press Tool Design and I was able to exploit this designing progression tools for the new dieing presses. Subsequently, having built a 10/15 ton Press to the original design and seeing the shortcomings we designed the rest of the series, 25, 50 ,75, & 100 ton.

This is the story of the Dieing Presses and you can see now from where the comment that CVA stood for`Copy Very Accurately` comes from. Some truth perhaps. My regards and best wishes to any other colleague from that time who may read this.

Great to hear from you Jack; we were meant to meet up, but I’m not sure what happened, my number is 01273 779114.

Regards Peter

Did my apprenticeship with Kearney & Trecker under Gil Percy 1970/71. Would love to catch up with Gil if he is still with us, have a lot to thank him for.

Just been having a conversation with my Granddad about his time working there. He worked there from 1952-1984, in the Portland Road factory. His name is Dennis Temple. Also my uncle Paul Temple worked there from 1972; he had quite a horrific accident around then. Almost had his arm ripped off by one of the machines when his coat got caught. Does anyone remember either of them?

Yes remember them both, we called Dennis Danny, he was a turner and also the union convener. I started my apprenticeship with Paul in 1970, we both moved to Hollingbury in September 1972. Yes Paul’s accident was terrible, I heard that it was Danny who raced to the machine to turn the isolator off, I also heard that he eventually made a good recovery, please pass on my regards!

So many people that I remember. Would love to get in touch with some of you. Lovely memories!!!!

Add a comment about this page