Almost 50 Years of CVA Machine Tool Manufacture

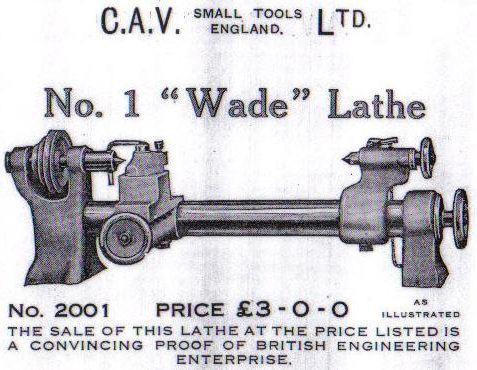

CVA Wade Lathe

Probably the earliest machine tool manufactured by CVA at Portland Road was the Wade Lathe, manufactured around 1926 when the Company traded as CAV. It was a basic design with a 3-step cone pulley used to achieve different spindle speeds. It sold for just £3.00, however no spindle drive was provided; power most likely being an optional extra, or provided separately by the user.

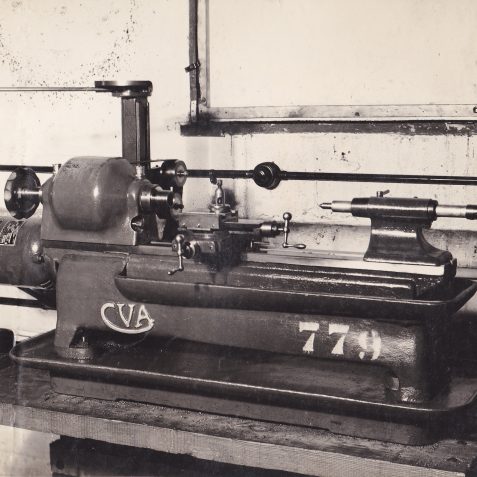

CVA Model 72 Bench Lathe

The Model 72 Bench Lathe was manufactured from the mid 1930s. The one shown is fitted with an H-Gear on the rear of the headstock, which provided variable spindle speeds. The H-Gear was also sold independently and was still manufactured by CVA up-to the early 1950s.

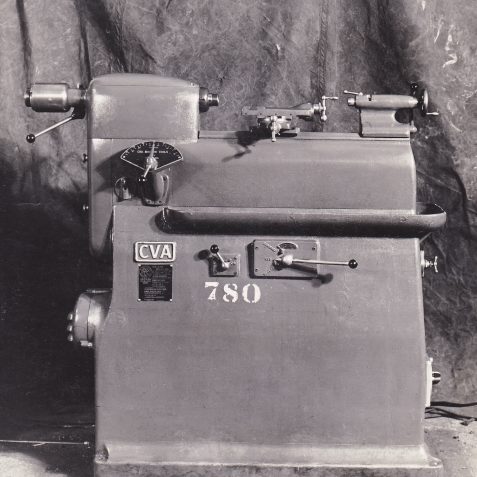

CVA Model 75 Floor Standing Lathe

The Model 75 Floor Standing Lathe was also manufactured from the mid 1930s. The H-Gear was integrated internally, with the on/off, spindle speed and direction selectors all mounted on the front. The tailstock could be replaced with a capstan turret, which enabled semi skilled operators to produce “quality” parts; probably an essential requirement during WWII.

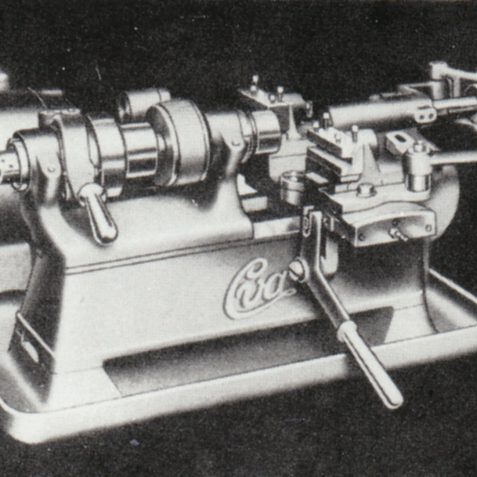

CVA Second Operation Lathe

Manufactured during WWII, the CVA Second Operation Lathe was a forerunner of the CVA Auto. For cutting motion, the slides were fitted with levers, presumably their presetting would determine the exact size and shape of the component; again an essential requirement for high production and semi skilled operation during WWII.

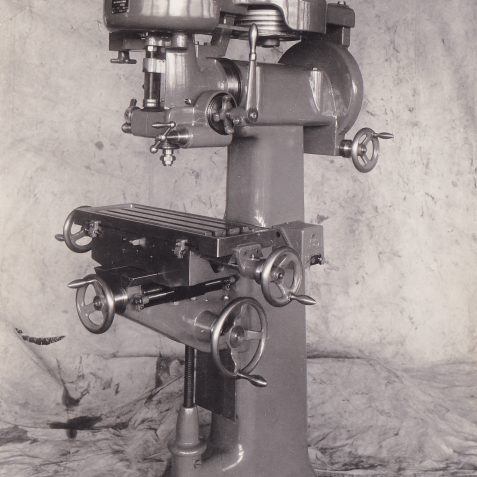

CVA Model 79 Toolmakers Die Sinking Mill

This “beautiful” and flexible machine was also produced during WWII, up until the very early 1950s. It had no power feed to the axis, therefore when CVA started to produce Kearney & Trecker Mills under licence from 1947, it was quickly superseded by their superior machines, all of which had power feed.

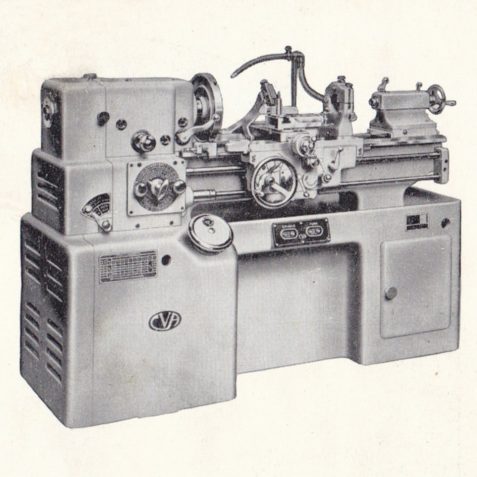

CVA 1 & 1A Toolroom Lathe

To complement the Model 79, was the CVA 1, and later 1A Lathe. Produced and sold from the late 1940s through to the mid 1950s, when it disappeared from sales literature and the Directors’ Report. The lathe was widely recognised by toolmakers as a fine machine, in fact many were also in production in their own toolroom in Upper St. James’s Street, Kemp Town.

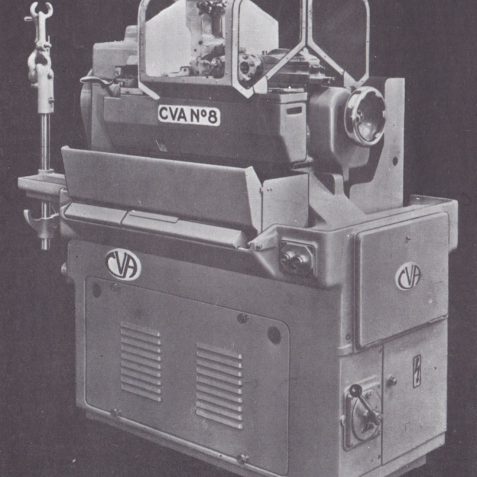

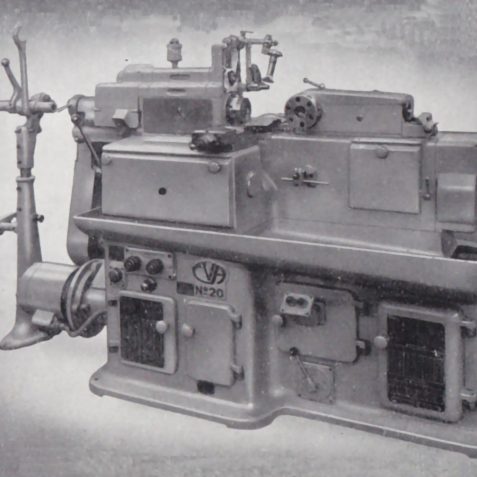

CVA High Speed Automatic Lathe (Auto)

Developed during the latter part of WWII; initially the No8 Auto was launched onto the market around 1947. This was followed by 3 other models, No12, No 20 and No 26. The numbers represented the bar capacity in 16ths of an inch. No 8 equalling ½ inch, No 12 equalling ¾ inch etc. The cutting tools were positioned to the part using cams, which were designed according to the component requirement. All models were equipped with the patented constant throw turret, amongst the many features. Although essentially a lathe, a wide range of other operations were possible, including milling, slotting, and deburring, enabling small complicated components to be completed automatically in a single operation.

Nearly 50 Years of CVA Machine Tool Manufacture

On the 22nd of May 1972 it was announced to the press, that the rights to the Autos had been sold to Brown & Sharp Limited of Plymouth, ending almost 50 years of manufacture of CVA machine tools. Auto production in Brighton would be gradually wound down over the following two and a half years. This would allow the company to concentrate on Kearney & Trecker numerical control and automotive machines.

A Lunch Time Mystery

Designers, machinists, foundrymen, electricians, patternmakers, welders, machine tool fitters; a skilled trade and gainful employment was had by many local men thanks to CVA. Times were hard in the early days, even tougher in the 1930s and wartime. How did the men relax during their lunch break at Portland Road? Did they have time to nip down to the seafront, play football in the yard, or was there another pastime? If you look closely the answer is on the page.

Comments about this page

Hi Peter, Nice piece! Darts was a very popular game in that factory I assume!!

Thanks Peter for another informative instalment about the local machine tool manufacturer CVA/KTM/FMT. I’m sure the older ex employees will find it nostalgic looking back at the products in the pictures. When I started working there in the early 70’s, the auto lathes were still manufactured in Brighton and I remember Gil Percy teaching us in the training school how to mill cams for the autos. The die sinking mill still looks a useful machine for a workshop today, ideal for one off and prototyping.

I believe the constant throw turret came in with the MK3 NO. 8. I spent six weeks at Hove in the late fifties on secondment as an apprentice. I did look over the wall to watch cricket.

I was a CVA apprentice during the 5 years 1948-53 and worked in the various machine shops that manufactured the parts for the world famous No. 8 Auto. I also worked at the ‘Cricket Ground’ factory in Hove, where the No.8 was assembled. I later became a Planning Engineer at Portland Road works and the Lewes Road factory, but left CVA in 1960 when I went to London to work as a Production Engineer at the Wandsworth based company, Projectile & Engineering Company. I have so many fond memories of my time at CVA. David Peckham.

Correct me if I am wrong but the designations 8, 12 and 20 were the maximum bar stock diameters the machine could handle in sixteenths of an inch, namely half inch, three-quarters and inch and a quarter.

Thank you for this page, I have just purchased a model 75 lathe which seems to have survived all these years in pretty good condition. It is minus the H drive and has step pulleys in it’s place. When I get it home and running I will send you some photos if you wish. Regards Graeme

I would love to see the photos: pedrogroves@googlemail.com

Hi. I worked at Eaton Road in the early sixties building TF mills, but they were still building a couple of 1a Lathes. I was told they were the last ones to be made, I am sure my memory is not playing tricks although its a long time ago

You could be correct Dennis, my date of mid 1950’s was based on when they appeared to stop promoting it!

Hi, I was an apprentice 1969 (5yrs) and then worked in the NC Maint dept Hollingbury until 1979. Anyone else out there remember those days. Saw Gil in Brighton appox 10yrs ago. What a great man to have been taught by, stood me in great stead for my working life. Some great memories too would love to catch up with anyone who was at K&T in the early 70’s.

Chris Ross (still in engineering in Sussex).

You are correct Doug!!

I wonder if anyone can enlighten us with the history of the CVA 1 & 1A tool-room lathe. The earliest ones seem to have been a copy of the American Monarch 10EE, except that the spindle drive of the CVA was more conventional. I’m told that some parts are interchangeable. This makes me wonder whether there was some official collaboration between Monarch and CVA. It would probably have been during WW2 so perhaps it was for the war effort. I’m sure that very high quality machines like this would have been in demand at that time.

In the description above it’s stated that the CVA 1 and 1A were made until the mid 1950’s. This must be wrong. I’m restoring one made in April 1961 and I’ve seen later examples. Even after CVA stopped making them a company in Dorking (Cole & Sons) continued for some years afterwards. These were sold as “Cole CVA” and were available into the 1980’s.

Finally, does anyone know if any of the drawings survived?

Hi Martin, thanks for showing an interest in my article about the CVA lathe. From my investigation using CVA sales literature and published yearly financial accounts, the 1A lathe was in those documents during the post war period and up until the mid 1950’s. I then noticed that in literature published after that date they no longer were promoting that product, sorry if my wording was misleading. I was aware of the connection with Cole & Sons, and perhaps your lathe was produced by them. My reason for this assumption is that in 1957 Kearney & Trecker purchased shares in CVA, and CVA started to focus on manufacture of K&T machines, although they did still manufacture some of their own products like the CVA Autos and CVA High Speed Dieing Press, but not to my knowledge the 1A Lathe.

Having worked on machine tools for many years, I noted that there are similarities in models from different companies. I don’t think this is coincidence, it just so happens that if you design a product aimed at a particular market, others who also want “a bit of that action” will also have similar products. Its a bit like cars of the mid 1980’s, they all seemed to have that “jelly mould shape” because that’s what the market dictated.

I am very sure there was no collaboration between Monarch and CVA; during WWII CVA started their collaboration with Kearney & Trecker and I don’t think dual collaboration would have been acceptable to K&T.

I don’t know what happened to the drawings, but I know a man who will know…….will ask when I next see him! Take care during these horrible times, Peter.

Hello . I was interested to read the various contributions regarding the CVA lathes made by K & T.

Some years ago I was a Sales Engineer with Dean, Smith & Grace Ltd. – probably the finest British built lathe. One of my aerospace customers had several CVA lathes which we totally reconditioned rebuilt as new. I remember going to Coles in Dorking to buy some spares, although they had ceased to build the CVA by then – this was in the mid 90s .

MARK RIGG

BRIDGNORTH

Hello again.

Regarding the CVA LATHE . In the past few days I have been offered a CVA lathe which, although running needs a bit of restoration. Many years ago whilst working for Dean, Smith & Grace, we got the job of rebuilding several CVA lathes for an existing customer and I went down to see Coles in Dorking to buy any spares they had. As Coles had ceased manufacturing the CVA some years previously, there was some discussion regarding DS&G acquiring the CVA drawings. Nothing came of this, but I wonder if the drawings do still in fact exist – Perhaps Peter Groves can investigate his contact! Coles don`t appear to exist in Curtis Road now.

I await any information.

MARK RIGG

BRIDGNORTH

Hello all,

I have so enjoyed reading up on the history of the CVA 8 in these pages. I have just inherited 2 CVA 8’s from one of our subcontractors. I am an indentured toolmaker by trade and after half a days training from 2 guys both in their late 60’s I have just set these 2 lovely old machines to work in a production environment. I made 2000 parts on Friday no hiccups with consistent sizes. I have orders for 250000 parts this coming week. I don’t know if anyone can help but I would be interested to know if its possible to age these machines by their serial numbers. Thankyou.

Hi Darren, in theory yes, but in reality doubt if there is anyone around who remembers! In the 1970’s with a new range of machines we always started the first one with S/N 1001 (so the customer didn’t know he was getting the very first one) I don’t know if we inherited this procedure or not and I don’t know what they were doing from 1947 with the No 8 Auto. I have often asked “CVA Old Timers” questions like yours but sadly they are too old to remember. Great that you have had success with your Auto, long may it continue! Peter.

My father had (and I still have) an old tubular bed lathe when I was just a child. With it he built a small model steam engine sometime around 1938-1940.

Yesterday I opened an old wooden chest to find that same lathe and I was delighted to see that although it has been dismantled, it is still complete. All the original screws and bolts are still there too.

On close inspection I discovered a name plate “The Wade Lathe”. It is a very simple lathe with just the three step vee pulley as shown in the photo of the brochure at the beginning of this page,

So begins a restoration project to return it to its former glory, but I need a little help. It has always been painted red, can someone let me know if it would have been that colour originally?

Thanks.

Lyall Austin

Forrestfield

Western Australia.

I don’t think there were many or any colour choices back then Lyall. Most of the early CVA machines I have seen were either slate grey or olive green, but the slate grey is much nicer and probably authentic. Good luck with your restoration!

Thanks Peter.

That’s interesting because there is no sign of any other paint colour underneath what remains of the very dark red. Oh, and I forgot to mention that it also had the three step cast iron drive pulley, treadle operated, but I suspect it has been thrown out, probably after my dad died in 1987.

Do you know if it’s possible to attach photos to this post as I’ve taken a few as it is at the moment.

Hi Lyall, it seems you can’t add photos, shame.

You could create a new page (titled : Restoration of CVA Wade Lathe)

Just write a few lines about your father and your memories of him and his lathe, and how you are restoring it, then attach the photos. Submit it under the Portland Road section, where it was probably originally made, and I think those of us interested will find it.

I would love to see the photos if you would email them to me:

pedrogroves@googlemail.com

Kind regards.

HI, ANYONE HAVE SPARES OR BREAKING A NO 79 MILL PLEASE HELP, NEED THE PARTS.

I HAVE AN EXCEL L3N bench lathe complete with a separate H gear drive unit same as that fitted to the CVA72 lathe I would like to source a handbook, patent number or any information on how to set up the drive unit, can you please help?

Regards.

Richard.

Add a comment about this page